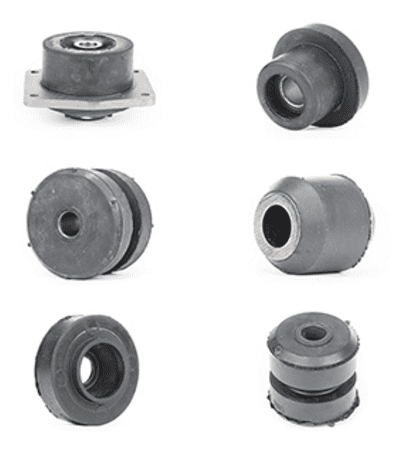

Our rubber isolation mounts are available in a variety of forms and designed to minimize vibration, shock loading and noise. High-load and high-capacity isolators have uses in many industrial applications to support and protect equipment and operators.

Binocular/Split Mounts

Binocular/Split Mounts are designed to minimize the transmission of noise and vibration in severe applications such as engine mounts. Severe dynamic forces in the static load direction, as well as the rebound direction are dampened to preserve equipment and provide comfort to the operator. Travel is limited in both directions by rubber in compression which provides snubbing.

binocular-split-mountsTypical applications for Binocular/Split Mounts include on-highway, off-highway and construction vehicles.

Features & Benefits

• Dynamically effective in all directions

• Prevent mechanical transmission of noise

• Accommodate misalignment and distortion

• High rebound capacity

• Easy to install with common tools

• Standard bolt torque assures proper assembly

• Fail-safe assembly

• Sized for English and Metric bolts

• Long dependable service life

• Economical

Center-Bonded Mounts

Center-bonded mounts provide flexible suspension systems to isolate vibration, control shock loading and reduce noise. Typical applications include engines, cabs, fuel tanks, pumps, air conditioning units, compressors and industrial machinery.

Available in a full range of rated load capacities and able to withstand shock loads of 10 Gs, these mounts effectively protect equipment and improve operator comfort.

Features & Benefits

• Vibration isolation in all directions

• Noise attenuation

• One-piece design for easy, low-cost installation

• Long service life

• Consistent performance because of permanently bonded design

• Shock protection

• Space-saving size

• Accommodate English and metric bolts

Sandwich Mounts

(Standard UNC and Metric Threads)

Sandwich Mounts are designed to minimize damaging vibration produced from equipment and machinery in operation. Sandwich mounts are constructed with specially compounded elastomers to give high-strength bonds. The simple design and unitized construction provide long life, low cost mounting systems which are compact, lightweight, easy to install and maintenance-free.

Typical applications for Flex-Bolt Sandwich Mounts include business machines; motorcycles; heating, ventilating and air conditioning equipment; light motors; appliances; shipping containers; feeders; compactors; and vibratory rollers.

Features & Benefits

• Economical

• Compact and lightweight

• Easy to install

• Maintenance-free

• Three size groups: small, medium and large

• Unitized construction

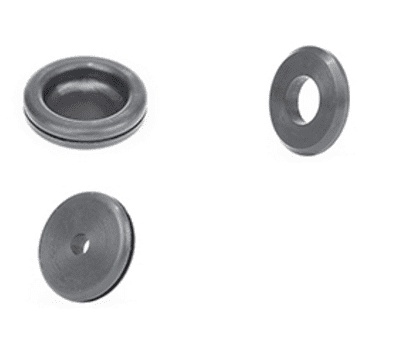

Grommet Isolators

Grommet Isolators are made of neoprene and natural rubber providing good isolation for disturbing frequencies above 30 Hz. Grommets are particular effective at absorbing and minimizing disturbance emitted from operating equipment operating for long periods. Grommets offer effective, economical vibration isolation for light loads. Suitable applications include: ventilation equipment, precision instrumentation and general industrial equipment.

Features & Benefits

• Economical

• Offer improved reliability in environments of harsh vibration and shock

• Space saving

• Oil resistant

• Effective vibration isolation and shock protection for light load applications

Hydromounts

Mounting engines to subframes and vehicle bodies must provide secure fixing of components and also dampen noise and vibration. Engine idling vibration combined with accelerating & braking torque produce severe operating conditions suitable for hydromounts. Hydromounts make possible amplitude-/frequency-selective damping in a compact and easy to install design.